Records of progress of orders

Monitoring the hours of work in individual centres (orders) helps the company management monitor and evaluate the employees’ work efficiency.

Using reader EP400* or HT200*, the system allows collection of data about production operation directly at workplace. The data is transferred to superior software, where it is statistically processed.

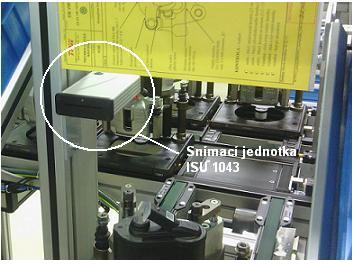

Reader ISU1043 is recommended for the systems that require card identification.

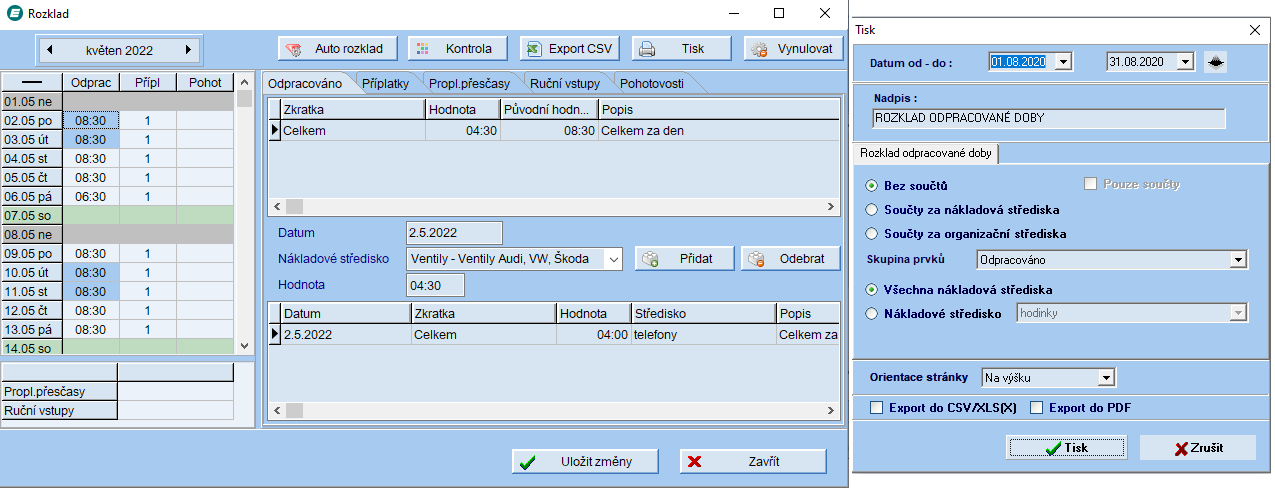

Basic program functions:

- monitoring hours of work in individual centres

- monitoring hours of work of orders (projects)

- option to manually sort individual figures (working hours, bonuses, etc.) into cost centres

- export into wage payment system

- tailoring the programme to fit the individual customers’ needs

The system is a part of a complex solution of identification systems supplied by ESKON s.r.o. Therefore, its outputs can be used also to calculate wages in combination with the attendance software and other applications.

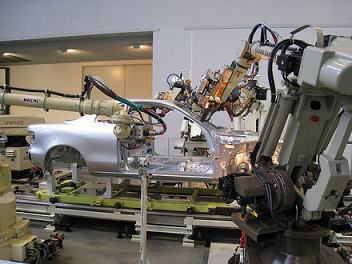

Managing industrial production

This application is used for identification of objects, e.g. pallets, containers etc. This application allows to achieve a high level of production processes automatization, which will result in a better productivity, reduction of operating costs, and minimization of human errors. The application is ideal for the sphere of production, logistics and transport.

Every object is equipped with an identification unit that guarantees unequivocal identification in the production process. For collection and storage of data we recommend our readers. All the data can be further processed by the application software and statistically evaluated.

For connection to central operating machines in the production and to other application that require only card identification, we recommend readers ISU1043. The readers can manipulate the machine (switch on/switch off), and record the operating time.